A good client of mine purchased this Elite Force HK 416C a few years ago with intentions to customize it. Unfortunately the project was canceled part way through as the company responsible for it suddenly went out of business. Sadly my client was given a small box with the rifle entirely disassembled within it. Thankfully he was never charged for the project, but that still doesn’t resolve his issue of owning a non-operational gun.

I was given a call a year later with a request to fix his gun. After chatting for some time and throwing around ideas, I decided to take on the project. We saw this as the perfect opportunity to make the AEG even better by using drastically higher quality components. We intended to achieve these three goals in order of importance: Reliability, Performance, and Good Looks.

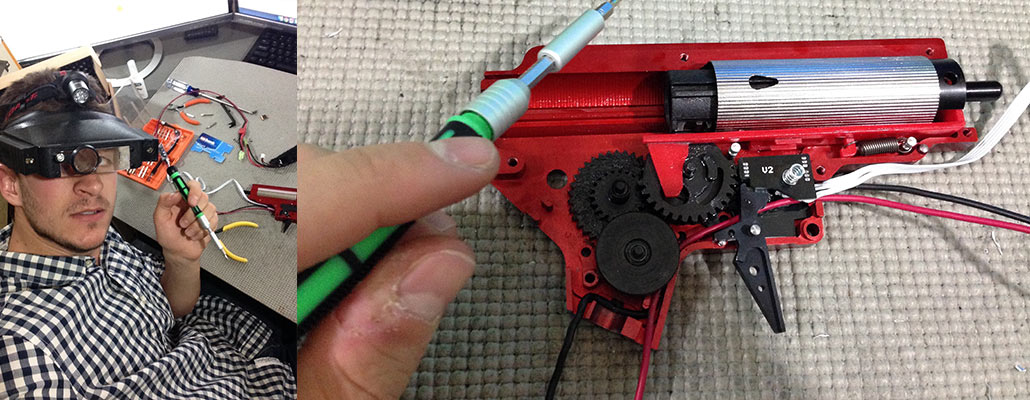

This project is still a work in progress, but it’s coming along very nicely. I’m extremely satisfied with the quality of these new CNC’d components from Retro Arms. I’m personally finding it difficult to go back to Chinese pot metal. The combination of the Lonex-A2 high torque motor, Siegetek 14.09 Gears, and the BTC Chimera is providing excellent rate of fire on a 7.4v Li-Po. We’re basically rebuilding the entire gearbox with aftermarket components, so getting everything to fit properly does take a little bit of modification with the dremel.

I also want to note that the gun was given to me in a sand blasted state. Apparently it was originally intended to be this way which is not good because it’s entirely exposed raw metal and the oils on your hand creates permanent stains on it. I’m going to get this Cerakoted in the color of Titanium when I’m done.

Do these make me look goofy?

Ok good. Things are coming along nicely. Gears are shimmed. Selector plate, mosfet unit, and speed trigger have been slightly modified to fit.

Filming in progress

Filming every step of the process is tedious work, but I know it’ll be worth it in the end!

Lesson learned. Don’t use SHS Steel Bushings!

I immediately ran into problems with my SHS steel bushings.

1. They are too thick: Shimming is impossible with these bushings. There’s no room for any shims with the combination of the Retro Arms gearbox, Siegetek gears, and SHS Steel bushings. It’s too tight for the gears to spin freely.

2. Too wide for axil: I tried to remedy the situation by sanding the bushings to make them thinner. I was finally able to shim, but faced a new dilema. I found the hole in the bushings to be significantly wider than the axils on the Siegetek gears. High speed spinning caused the bevel gear to vibrate spiritually. No matter what I tried, I couldn’t get it to spin smoothly.

Solution: I replaced the bushings with Lonex Steel Bushings. These are super thin and had a tighter fitting within the gearbox shell. Much better now!

JB Welding on SHS Bushings

Applying some JB Weld I got at the hardware store to attach the SHS steel bushings. I decided to go with steel bushings instead of bearings for increased reliability. I personally have never had bearings fail on me, but I have seen too many stories of them failing on the tech forums. I don’t want to run that risk.

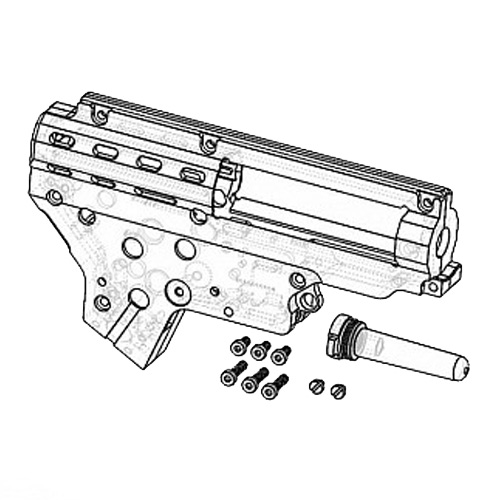

These slots are going to make a breeze to tech on

I really like these extra view slots and wider grooves that Retro Arms put in. The view slots is going to make it a lot easier to see what’s going on inside. Handy for things like adjusting bevel to pinion gear. The sturdyness and light weight is astounding. Definitely lighter than your typical gearbox. The deeper grooves is going to help with the thick wiring we’re going to use with the BTC Chimera. Most other gearboxes have to be modified to accommodate thicker wiring.

Yes! It came in!

Sweet! My new Retro Arms gearbox has arrived. I’m loving that red. My logo turned out great as well.

The original motor

Here’s a look at the original motor. Definitely a good motor for a stock AEG, but we need something with more torque to spin those high-speed gears.

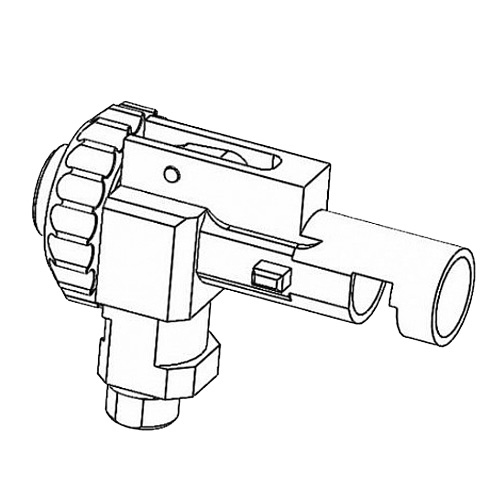

The original VFC Gearbox

Here’s a look at the original gearbox that comes with the 416C. It’s manufactured by VFC. Definitely a good gearbox that you don’t want to throw away, but for this project we want something even stronger. Something we know will never break. I could save this for another project.

Let’s see what I have to work with

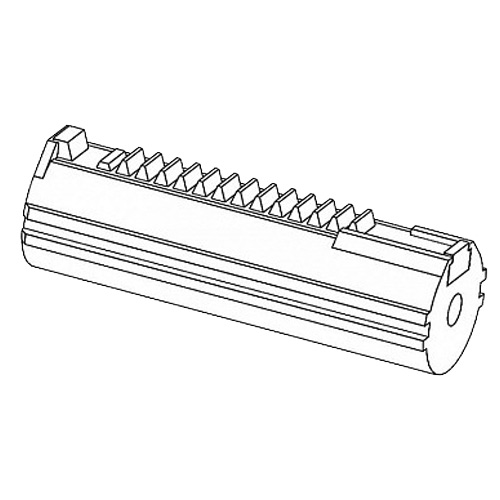

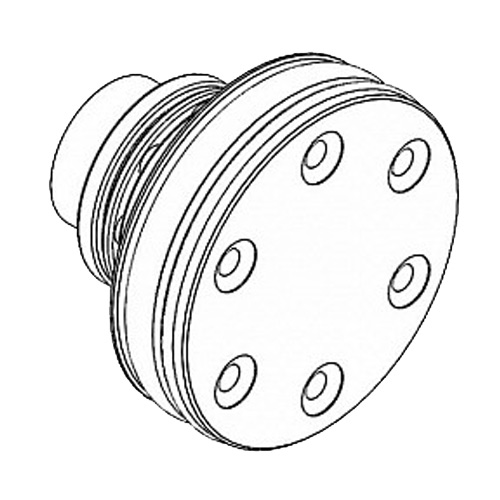

Hmmmm. Let’s see what’s inside this small box of sadness. This pic doesn’t even show everything that I have to go through. One thing I noticed is there’s already damage to the cylinder in this very expensive bore-up set.